R&D+i

We own a well equipped

laboratory

We create more value through our innovation strategy, with ambitious targets and measurable results.

Innovation Projects

- Basic castables, Alfran Mag 85

- Cement-free castable: Drytech

- Drytech Clean 40 HG

- Tix 80 NW

- Alfran TDZ, Anti-Wear Solution

- Alfran Steel-Tech

Collaborative projects

- HORUS: Smart reheating furnaces for competitive and sustainable iron & steel processes.

- CERES: Advanced research in the field of mineral-based industrial waste.

- NEOSOLAR: Development of innovative parabolic trough solar thermal plant concept.

Lines of research

Engineering of multilayer coatings fordifferent industrial processes

Design of refractory materials

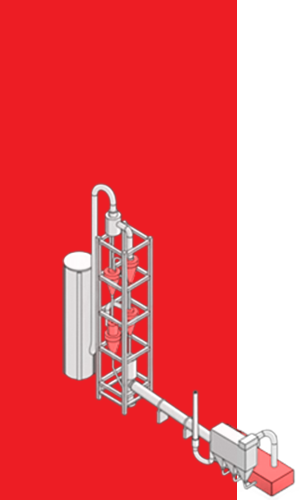

Energy Efficiency and Sustainability

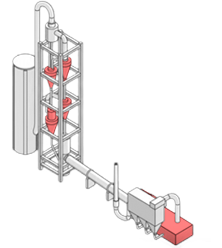

More efficient and technology-based installation methods and equipment.